INTERVIEW

Andrea Bortolin From 3T on Made in Italy, Control and Sustainable Innovation

3T's Product Manager on the brand's Italia program and how homegrown production helped make a better bike.

Andrea Bortolin, Product Manager at 3T Bikes, is waving his hands around like a conductor at La Scala. He's telling me about the origins of the brand's new 'Italia' program, an initiative that's brought the production of 3T bikes back to Italy after decades of exclusively off-shore manufacturing. The situation is, in itself, unique, as I'm usually faced with a screen. However, thanks to our bike show, Regroup in the Desert, this affable Italian has flown from Presezzo in Bergamo to Arizona to be with us, and, poor man, sit here with me and explain something he's probably done a few times before.

You may know 3T as an Italian brand founded in 1961, a component maker, and, since 2016, a fully-fledged manufacturer of bikes. You may have even read our interview with the CEO of Factor Bikes, Rob Gitelis, who described how, in a former life, he helped 3T off-shore many of its products to Taiwan. And most are still made there, of course, but not the 3T Italia range of bikes. No signor.

“Our dream has always been to bring production back to Italy,” says Andrea, with a rousing fortissimo. “So in 2017, we began the long process of investigating whether producing a line of 3T bikes in Italy was feasible and sustainable; whether it was possible or a pipedream!”

And possible it was, but not as the brand had been making its bikes in Asia, explains Andrea. “We had to create an entirely new process, one as close to home as possible: inside our existing HQ.” This isn’t my first Rigoletto, so I ask Andrea a difficult question and hope he doesn’t take offence. Was the Italia program a genuine engineering project or a marketing opportunity? “No!” exclaims Andrea. “It was always about the product, about being entirely Italian once again. Yes, there’s a communication part that we’re proud of, but that came later after the hard work of finding a way to produce not just one-off bikes but production runs of 3T bikes in Italy, now and in the future.”

But there’s nuance here. While 3T wanted to start making bikes in Italy, as Andrea talks, I begin to understand that the overarching reason was control. “Yes, we knew that if we could make our bikes under one roof, design, develop and produce in the same place, with the agility to retrace our steps, and refine or witness the result as it happened, we could make a unique product worthy of the Made in Italy label.”

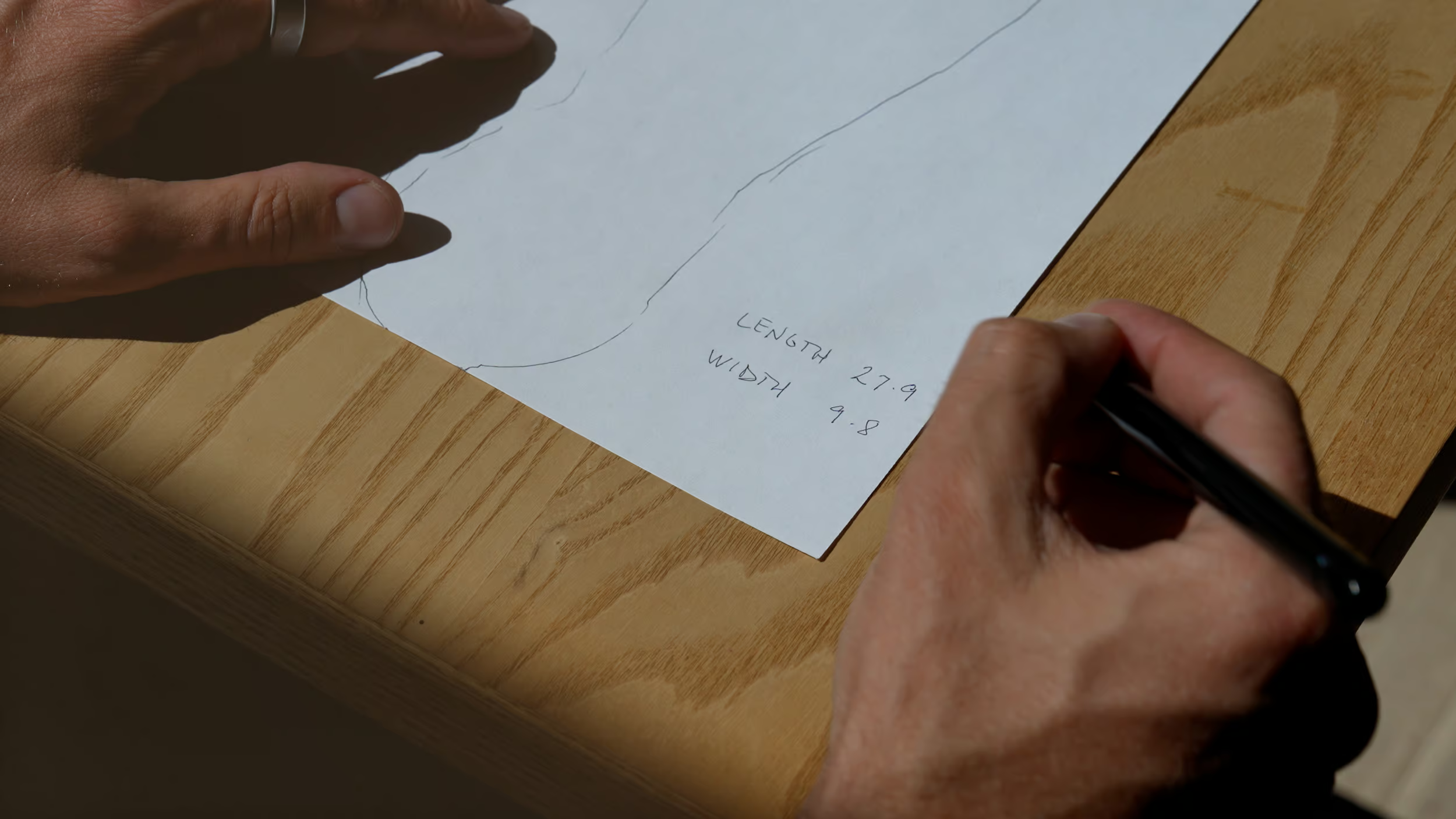

What followed, he says, was a long and arduous journey of analyzing materials and production techniques before 3T’s engineers arrived at a method that incorporated proprietary filament winding and resin transfer molding, a concept that foregoes the pre-preg ‘ready-to-mould’ carbon fiber of the wider industry in favor of a process more akin to textile production. “It unlocked the project for us,” says Andrea of the filament technique. “If we had used rolls of ready-made carbon fiber, we could not have created a unique, sustainable and materially efficient product. It would have required too many hands and hours to produce each frame.”

With multiple machines winding threads and blending different types of carbon fibers to create tubes, the filament winding process is as beautiful as it is simple. “There are so many wonderful advantages of the technique,” Andrea adds, “one of which is that it allows us to run a single filament the length of a tube, like, for example, from the bottom bracket along the entirety of the down tube, which gives us the ability to tune ride feel in quite specific ways, and offer exceptional strength.”

3T’s Italia range consists of the fast-gravel Racemax Italia, the hardcore explorer’s Extrema Italia, and the road-going Strada Italia, each bike designed and made at the brand’s HQ in Bergamo. As we diminuendo away from the fundamentals of how 3T creates its Italia bikes, I ask Andrea about the brand’s design process and how a 3T frameset comes to life. “We started making bikes in Asia in 2016,” he notes, “and from the first frame, our design process has remained the same: we start with the desired tire width, and from there, we craft the geometry, the aerodynamics and the wider frame. Our design philosophy for the Racemax Italia, Extrema or Strada is the same, despite their very different ride profiles.” To that point, how does a 3T Italia bike ride? “Super reactive and very easy to handle,” he legatos. “Compared to the Racemax we make in Asia, which launched in 2020 in pre-preg fiber, the Italia version is even more reactive and even easier to handle,” he admits. “The Racemax is already a great platform, but the Italia, because of the new techniques, the control we were able to exert and the agility of in-house production, we could go further and amplify its properties and take it to a new level.”

I’m interested to learn more about 3T’s approach to design. “We start with tire width because it is key us to working towards a geometry that helps us make the bike’s performance accessible to everyone,” he explains. “First comes frame angles and fitting – stack and reach. We tailor the platform to help a rider stay in an aero position for a long time, efficiently and, we might say, realistically!”

"We knew that if we could make our bikes under one roof, design, develop and produce in the same place, with the agility to retrace our steps, and refine or witness the result as it happened, we could make a unique product worthy of the Made in Italy label."

ANDREA BORTOLIN

What Andrea means is that despite the speed of any of the Italia bikes, if you race one or head out for a long, hard ride or take off for a multi-day trip, 3T’s engineers would have you reach the last mile in better shape than your fellow rider, less tired from having been in a less than perfect position. “Exactly,” agrees Andrea. “Even pro cyclists are starting to realize the benefit of pulling back from sheer performance and rebalancing in favor of overall comfort at a small cost to aerodynamics. For example, it’s not uncommon for a rider to have a spacer under their stem, which would have been unthinkable in the past. But, if that rider is more comfortable for longer, they will be faster and fresher for longer, potentially negating the aero advantage that an extreme position might offer.”

All this talk of riding is giving me the jimmy legs. And I know there’s a Racemax and an Extrema right outside, ready for the off-road. But which one should I choose? “Well, if you are looking for a fast gravel machine, a performance-driven frameset with a road feel that fits up to 45mm tires, measured, the Racemax might be best,” laughs Andrea. “And by the way ‘measured’ is the operative word. “There is no real width standard between brands, models, tires and rims, hookless or hooked, which is why we emphasize the importance of measured width – the width of an inflated tire.” That’s the Racemax Italia; what about the Extrema Italia? “It has up to 57mm of tire clearance, while maintaining a minimum of 6mm of space between tire and frame at any point. That’s great for muddy conditions – extreme situations.” And it’s gravel sub-genre? “Racing and bikepacking. It’s a bike built for exploring and competing at a high level.”

Andrea mentions the 780km (485 miles) 2024 Badlands race in Granada, Spain, and the success of 3T rider Alex Martinez, who chose to ride the event with the Extrema, fitting 53mm rubber alongside a SRAM Red 1x / 13 groupset. “He won the race, taking the flag in just over 42 hours. And that with 16000 meters (52000 ft) of climbing!”

As if on cue, I become aware of the sound of the birds outside and a moment of calm amidst the ebb and flow of the show. Andrea recognizes it too, a fermata that marks the start of the end of our conversation. I thank Andrea for taking the time to talk. He’s a gracious and passionate representative of 3T, a vibrant reminder of the power of reinvention, of bikes and their power to reinvent. We’re excited to be part of the 3T journey wherever the road goes.

FEATURED PRODUCTS

3T RACEMAX ITALIA

3T’s heart rate-maxing Racemax Italia is a gravel bike built to reach the flag with flying colors. Blending comfort, control and a devastating turn of speed, the Racemax rewards your best efforts with unlimited enjoyment.

FEATURED PRODUCT

3T EXTREMA ITALIA

A gravel bike built for the most challenging parcours on the planet, 3T's Extrema Italia carried the day (and night) at the Spanish Badlands event. Enough said.