INTERVIEW

Gravel pro Skyler Taylor on His Debut Race and Win for Sarto

After powering to his first win for Sarto aboard his custom Raso Gravel, we spoke to fast-moving US pro gravel cyclist Skyler Taylor to find out how his race played out and why 2.2" rubber rules

The most obvious question to ask Skyler Taylor after his debut win for Sarto Bikes at the UCI Highlands Gravel Classic this past weekend is: how are the legs? "They're doing alright, thanks!" he replies. You might expect that at 29. But the way Skyler played his race over the 68-mile course in Arkansas revealed a tactically astute, decisive and undeniably rapid rider with a maturity that belies his youth - a killer combination.

Over Zoom, piped in from his home in Marin County, the impression of eager speed holds. Skyler looks ready to leap out of the door and turn his pedals to a blur, just for the hell of it. Although this week, he’ll have to resist the urge. “I’ve been training full-on since mid-November,” he says. “I have a few days off the bike now to rest. Then, starting next week, I’ll build toward Unbound with a three-week training block.”

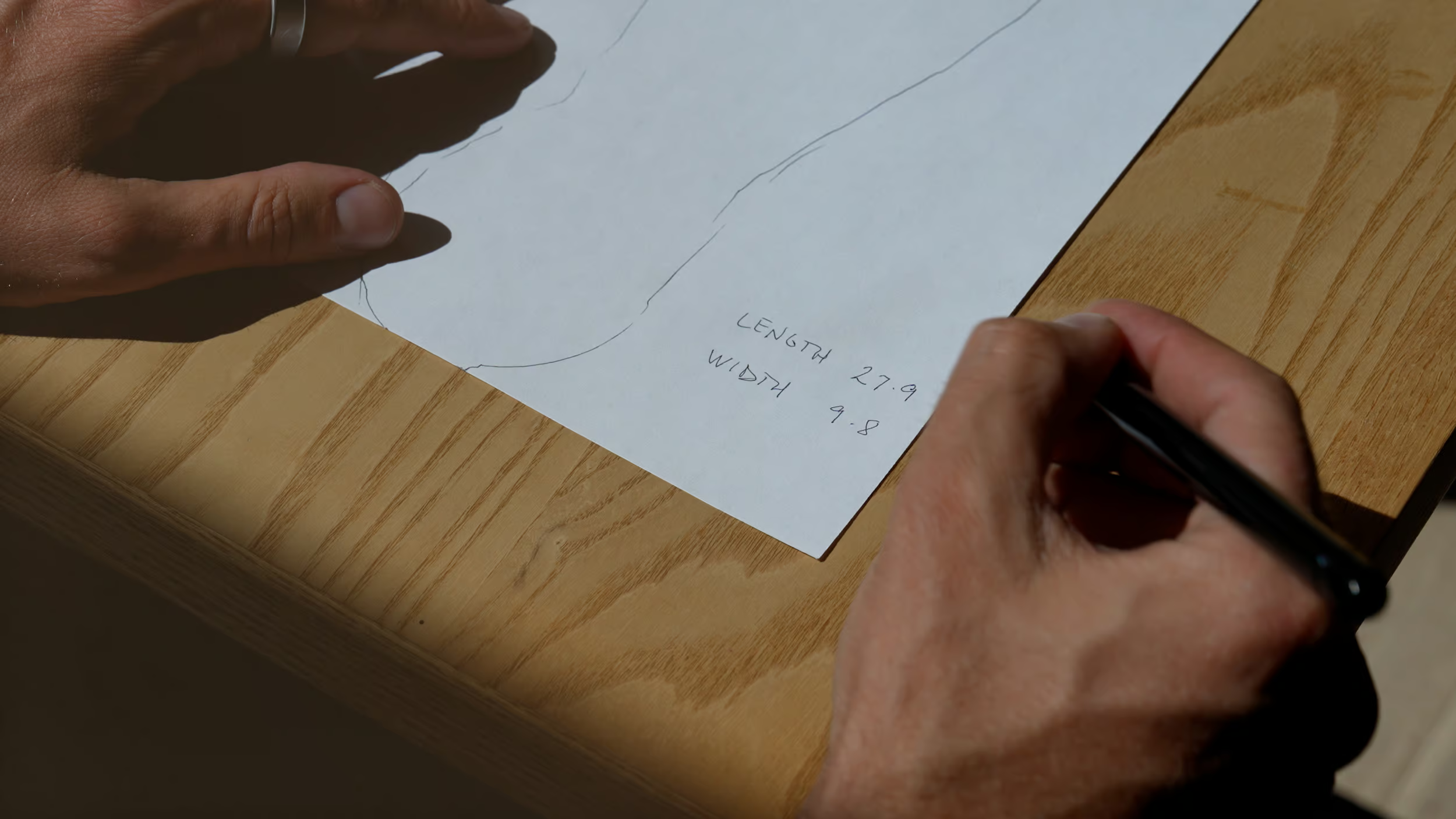

Before we get to the to and fro of the Highland race, we better back up a bit and talk about the bike Skyler rode to victory, his brand-new custom Sarto Raso Gravel. We heard on the grapevine he only got it a week before the event. “Yeah, that’s right!” he laughs. “We received the frame with only days to go before I was set to fly out and got it built up in under a day. I managed to snatch two rides on it before the race – once of which was in Arkansas itself.” It’s an understatement to say he must have felt at home from the first mile. “Definitely. Sarto did a nice job making sure we dialed in the whole geometry to align with my prior road and gravel bikes, so I was pretty confident that it would feel good once I got on it. And sure enough, it started to feel really nice after only a few moments. After a few miles, I realized I was riding something pretty wild. It’s an amazing bike.” A quick numbers check with his coach, the renowned Craig Upton, followed, and Skyler took off to Arkansas for his debut ride as a sponsored Sarto racer.

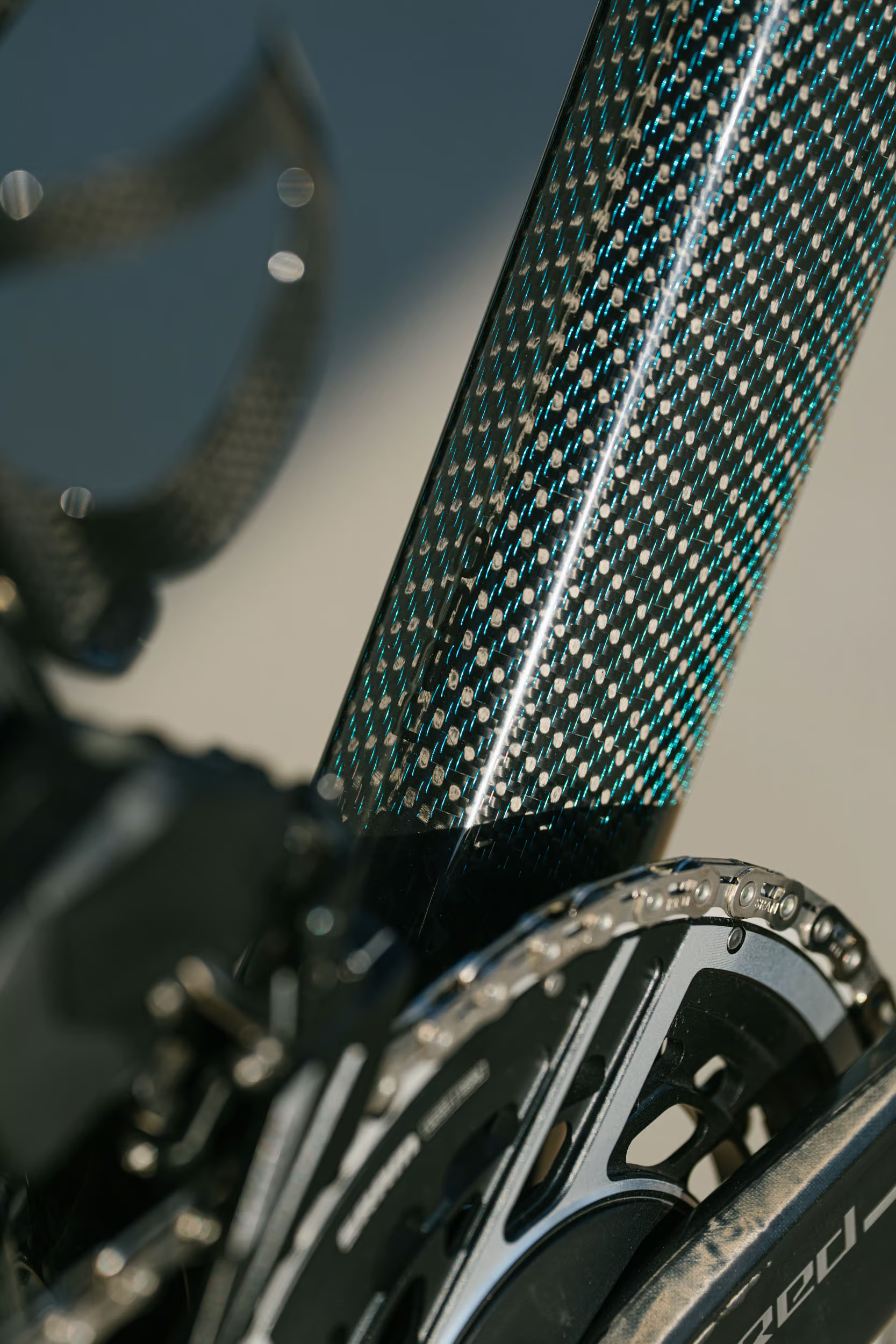

Skyler’s Raso Gravel looks incredible, with wide 2.2″ Continental Race King tires that speak to his experiments in speed and journey to discover the nature of the fastest gravel tire setup on the world stage. “I believe mountain bike tires are the superior choice,” he says. “On my last bike, I was doing crazy things, shaving off the knobs to make wider tires fit where they wouldn’t. So to have a bike like the Raso Gravel that can accommodate up to 2.2″ tires front and back and still have clearance to spare is a game-changer.”

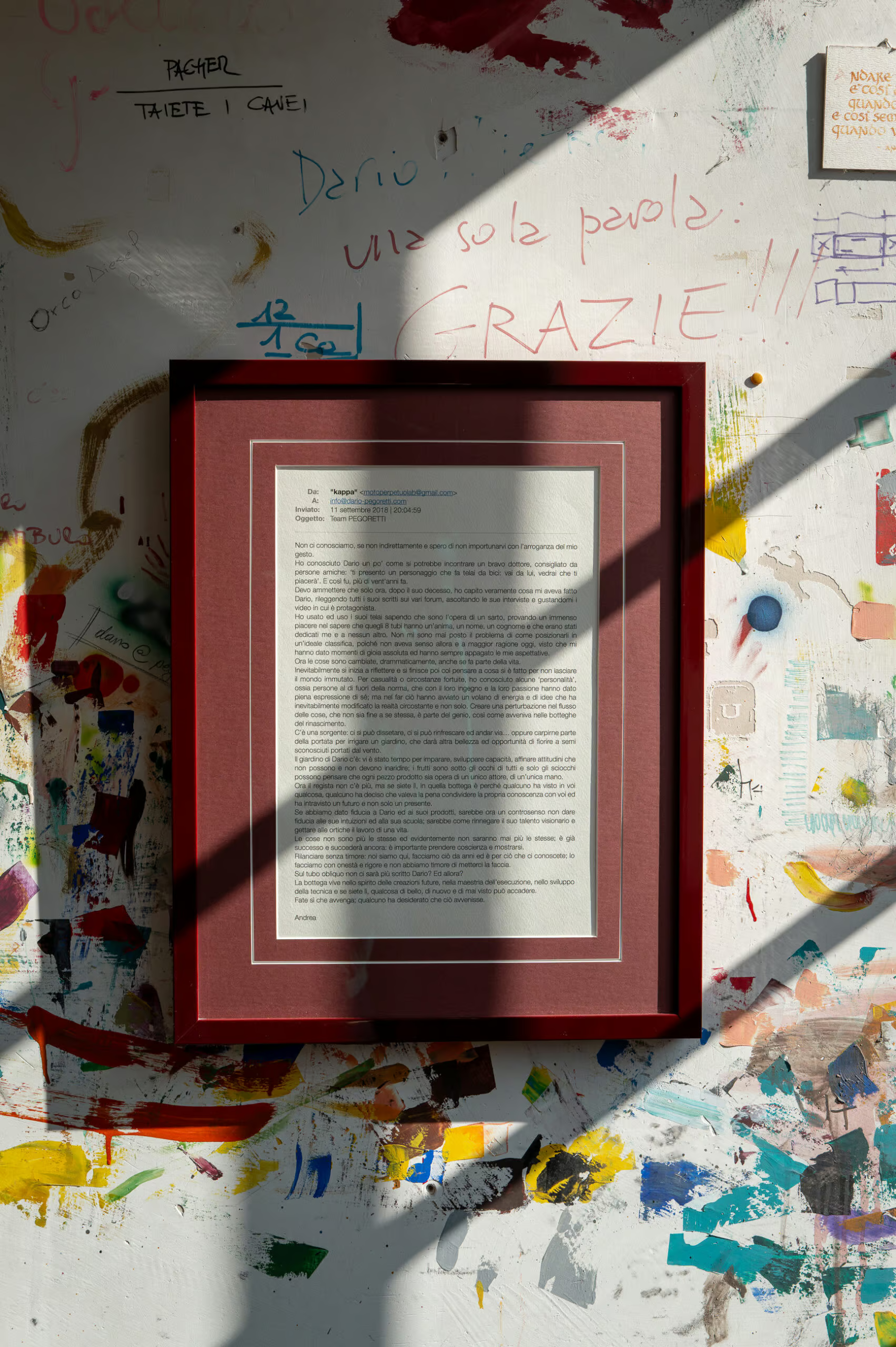

That extra room to maneuver came directly from Skyler’s feedback to Sarto, who was introduced directly to the team in Italy by Regroup’s very own Pete, who has a close relationship with Sarto. When Sarto shared some of their early ideas for the Raso Gravel with Skyler, he made some suggestions as to the rubber the fastest professional gravel racers in America were rolling, and in turn, directly influenced the development of Sarto’s new bike.

“A lot of the top US racers, myself included, were doing a lot of testing in real environments,” he says. “We’d take two sets of wheels and two different-sized tires at different pressures and run down a course a bunch of times to see which was the fastest. We all came to the same conclusion: the mountain bike tires were more comfortable, more confidence-inspiring and straight-up faster than gravel tires.” Even taking into account the rolling weight penalty that comes with larger rubber? “Yes. To give you an example, I did an uphill test on a paved road climb with a 50mm very light gravel tire versus a much heavier 2.2″ Continental Race King tire, and the 2.2″ rolled faster. It blew my mind.”

What does he put that down to? “I’m no physics expert, but there are suspension losses and things that move outside of the tire – your body weight, the ability to roll over small blemishes on the surface. There’s obviously a lot of work to do in the future for this to be something that extends outside of the pro gravel circle, but to me and my fellow racers, it’s been pretty clear at this point that there is a competitive advantage to having a bike that can take 2.2″ tires.”

Skyler points out the false sensation of fast that comes through riding thinner tires. “They feel quicker because you receive more vibrations through the bike which your brain receives as speed,” he explains. “So you’ll ride a thinner gravel tire, then a wider mountain bike tire, and the gravel will feel faster. A lot of people seem to struggle with that perception problem.”

Did the Highlands Gravel race feel like the ultimate realization of his testing, a chance to ride a true 2.2″-enabled gravel bike? “For sure. The Sarto is one of the first gravel bikes on the market to accept a 2.2″ mountain bike tire natively. Before the Raso Gravel, while I might have ridden a 2.2 on the front, I always had to go down to something like a 2.0 at the back.”

"On my last bike, I was doing crazy things, shaving off the knobs to make wider tires fit where they wouldn't. So to have a bike like the Raso Gravel that can accommodate up to 2.2" tires front and back and still have clearance to spare is a game-changer."

SKYLER TAYLOR

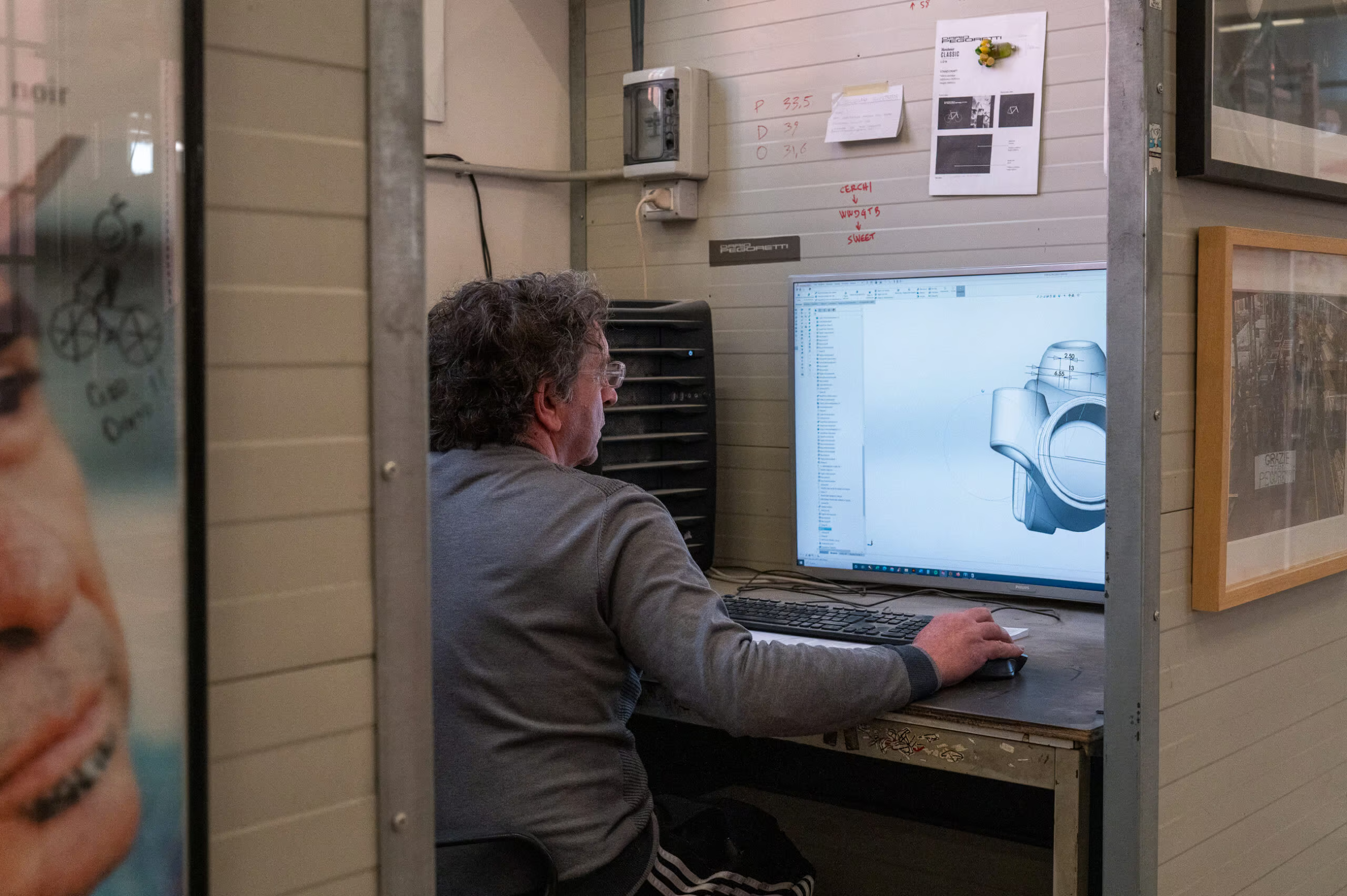

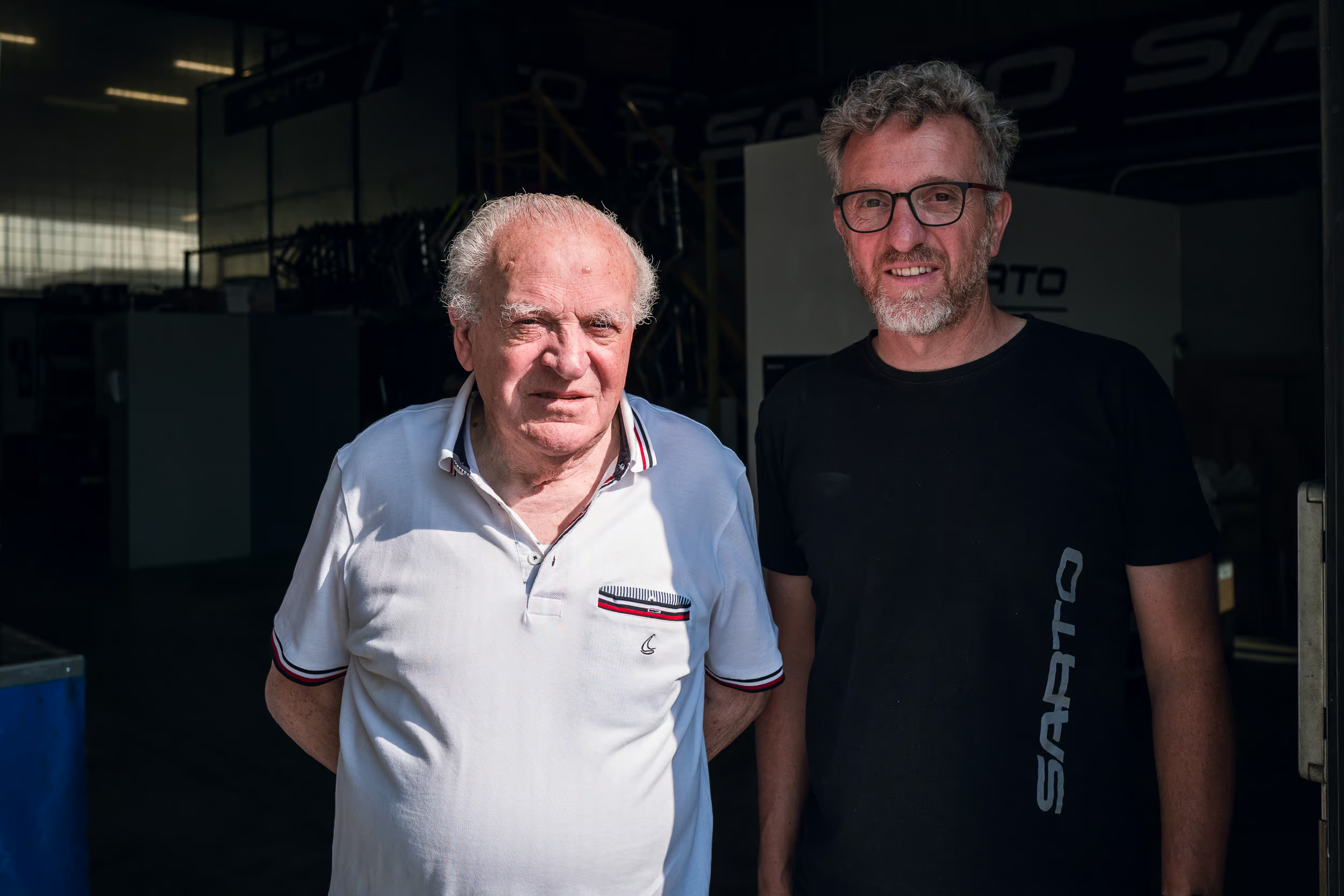

Of course, the Sarto goes a lot further than mere tire clearance. Skyler’s Sarto is tailored not only to his geo but to his riding profile, with a custom frame layup developed for him alone; such is Sarto’s expertise in crafting bespoke carbon fibre bikes, brought to life in-house just outside of Venice, Italy.

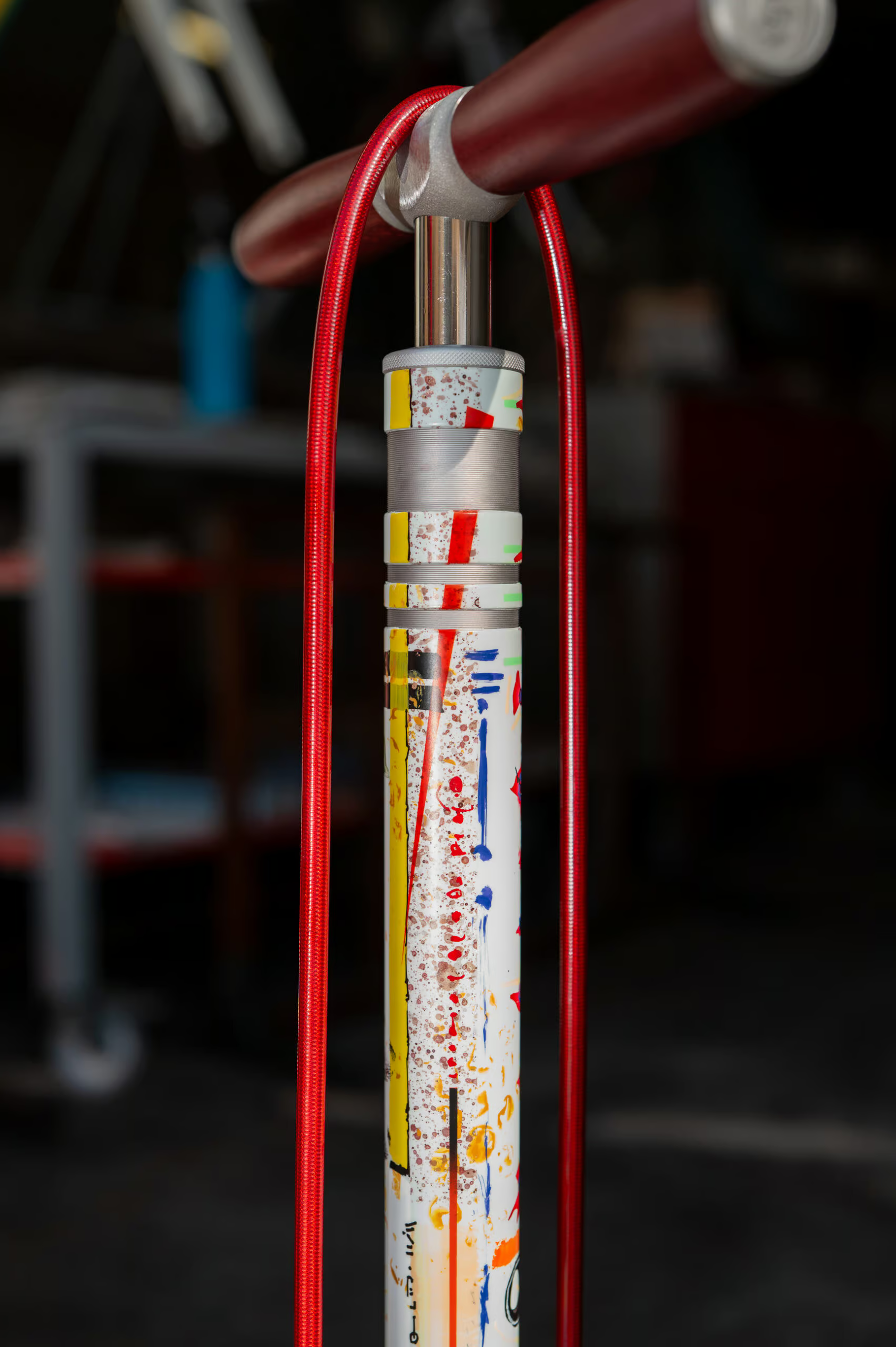

And it was to Italy that Skyler flew a few weeks ago to sign his deal. What was it like to visit Sarto? “I’d known about them for a few years, but to visit them, knowing that they were so flexible and open to ideas, was a special experience,” he says. “I’d never been inside of a factory building bike frames, so that was super cool. Seeing them bring tubes and frames to life was incredible, as was seeing how they repair carbon. There was real warmth from the team and a special energy. Enrico, Tommaso, Chiara – everyone was so welcoming.”

Looping back to this past weekend, what did the course look like? “Kind of classic – a lot of 1-5 minute climbs where you’re just punching full gas over and over.” Steep pitches? “A variety, but some were 15%, kind of like the cobbled classics. There were also some pretty rugged downhills, and with my mountain bike background and bike setup, they presented an opportunity to put some of my competitors under pressure.”

How did the race play out? “The first decisive climb was about 12 miles into the race, which allowed a group of four of us, which included Tim McBirney, a supremely good time triallist, to get away, so I knew we’d probably have the horsepower make the break last. We also had a Colombian pure climber, so between us all, we had our bases covered!”

In any race, there comes a moment when the riders in the break start getting twitchy: they know to have a chance of winning against riders with different strengths, they need to make their move. But with a group that included such strong riders, how did Skyler pick his moment? “The last decisive climb was about 10 miles from the finish,” he explains. “I’d pre-ridden it and knew it would be pivotal. It was steep enough that I knew I could put serious pressure on the others, an effort that whittled the group down to me, Tim and the Colombian rider. Another effort on a windy false-flat section dispatched the Colombian, and Tim and I pushed on, working together to make the break stick so we could tussle it out for the sprint.”

But Skyler couldn’t lose Tim. “No matter what I did, getting time on a descent, he came back,” he says. “So I figured I needed to wait for the sprint. I felt like I had the edge there, but only over a short distance as I knew Tim could wind up the wick and come back at me. I also knew the last section had some long grass that felt like riding through sand, which would favor the stronger rider. To have a chance of winning, I would need to stay behind Tim or risk being mown down. And that’s how it played out. I kicked around him with about 50 meters to go and managed to get across the line with about a second to spare to take the win.”

Quite a debut! “Thanks. Yeah, it was a magical weekend, and I was so pleased to get a win under my belt for Sarto to start the season.”

We’d be remiss if we didn’t ask about Skyler’s build. What was he riding with? “I went with a mullet-style setup, opting for SRAM’s latest gravel groupset, with a 1x upfront and a 10-46 at the back. Wheels came via Duke, a brand that makes lovely handbuilt products out of France.”

With Unbound on the horizon, will he carry the same setup to Kansas? “If it gets muddy, I might have to bring the tire width down a bit, as it’s often so bad at Unbound that even walking becomes hard. But if it’s dry, I’ll probably have more or less the same setup.”

Skyler might be a new face to the Regroup community, but he’s already an experienced racer, known in his early years as a mountain biking specialist. Having ridden and raced since he was a kid, Skyler spent time on the US national MTB team racing World Cups and other high level XCO races as a junior and U23 before stopping racing to go to university. Post-studies, he picked up the race number again, gaining traction with great results at the Norcal Grasshopper Adventure Series, as well as a win and a pair of second places at the famously hard Leadville stage race. But for all of his racing, this year is the first time he’ll be lining up as a professional bike racer. “I’ve been holding down a job in tech at the same time as racing, but for this year I wanted to see what I could do with a sole focus on the bike,” he says. “ So I took a break from work, and gave myself a year to see what I could do. Although I hope it will be more than a year!”

If the first race of the season is any indicator, the future is Skyler’s to decide.

FEATURED PRODUCTS

SARTO RASO GRAVEL

'Dream Faster,' says Sarto, but the brand might have said 'forever' - throw a leg over the Raso Gravel, and you won't want to come back down to earth.