A Bottom Bracket for the Ages: The CeramicSpeed ALPHA

Getting an inside line on the Danish brand's new ALPHA bottom bracket with Paul Sollenberger, Head of Product Education.

November 19, 2025

visibilityPEOPLE

Over coffee on the fringes of Rouleur Live, we spoke to Lightweight's VP Sporting Goods to learn all about the brand's new ART project.

WORDS

Peter Harrington

PHOTOS

Peter / Lightweight

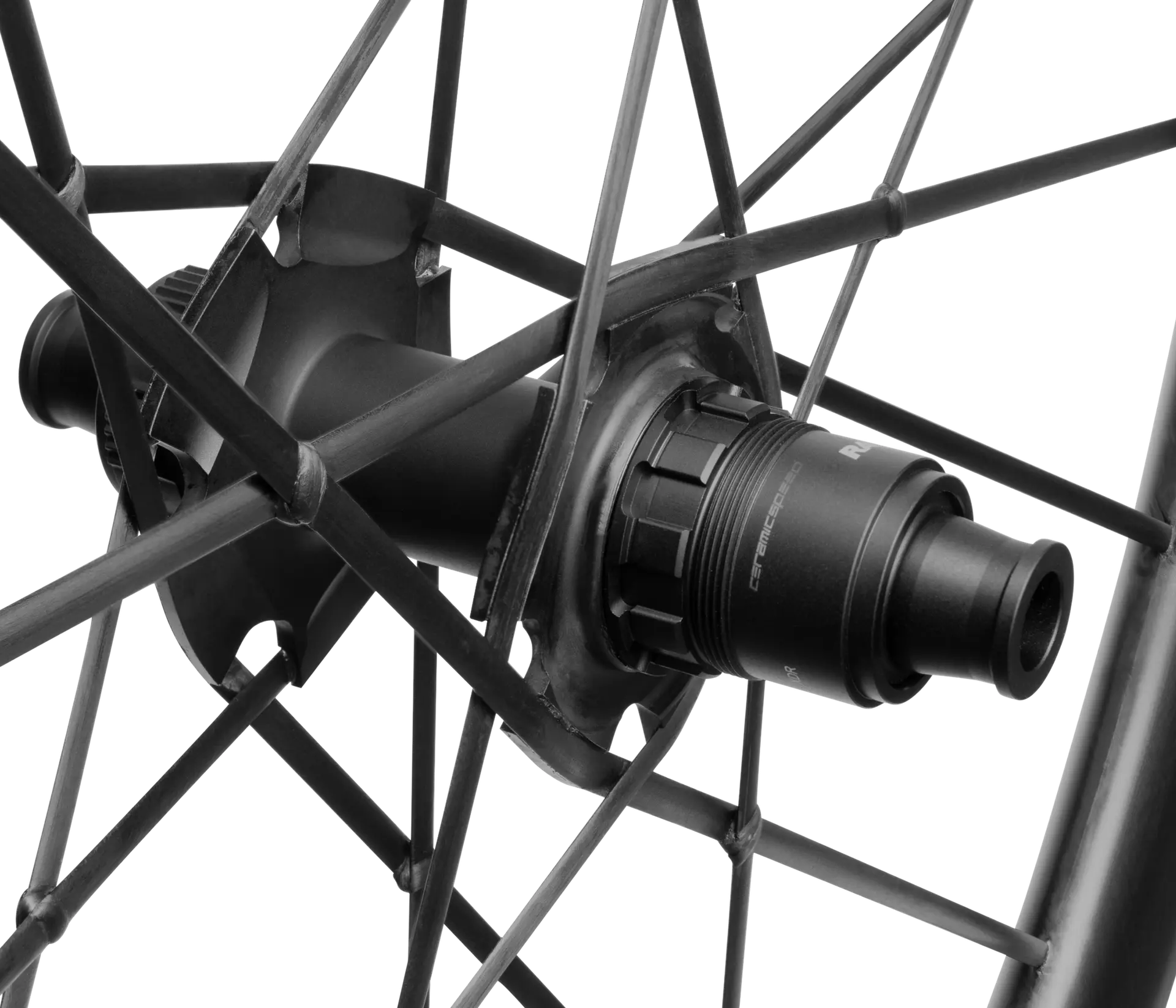

What do you know about Lightweight? Capital L. Not the adjective. Although, naturally, they are. We're talking bicycle wheels. Specifically, Lightweight wheels. Adjectives aside, each Lightweight wheel is handmade in Germany, a product of countless hours of work, extreme precision, decades of human experience and a combination of space-age materials that would appear to have more in common with moon landings than mountain summits, which is not a coincidence: Lightweight's parent company makes highly complex composite things for satellites.

Now that we’re on the same page, follow us to London and the fringes of Rouleur Live. Take a sharp left from the main entrance of the Truman Brewery in Shoreditch, where the show is preparing to open for the day, to a bustling coffee shop that doubles as a roastery and doubles again as a meeting place. On my right, with an espresso, is Adam, the founder of Regroup, who flew in from Arizona earlier in the week. To my left is Christoph Sawitzki, Lightweight’s Vice President of Sporting Goods. He has tea, which is very sensible. Rouleur is a marathon. Mine’s an americano.

We’re all here to talk about the brand’s new Alpha Rib Technology – ART for short. Given that ART rewrites the Lightweight design book, it’s fair to say that it’s not so much new tech as a new chapter for a brand that started in a German garage in the 1990s with only an idea and a Leberkäse oven to its name. And not really even the latter – Lightweight as a brand name didn’t emerge until a few years after that.

At the time of writing, a search on our site won’t reveal anything Lightweight other than this piece, but expect that to change. We’ve always had a relationship with Lightweight, and there are more than a few Regroup Custom builds in the wild shod with Lightweight wheels, but, for whatever reason, we’ve never cemented the relationship and made it more than a one-off. Our meeting today, and the Meilenstein ART wheels we have on pre-order with the brand, are timely steps to rectify that.

“I’m originally from the Harz mountains”, says Christoph, as we begin what feels like the business version of a speed date. “It’s close to Brunswick and Hannover. I was always a cyclist, which explains why I am in this job!” There’s something of the road about Christoph’s demeanour, so when he tells us that he rides up to 8,000 miles a year – the sort of distance that hollows cheeks and sharpens the nose – I’m not surprised. How does he find the time? “Ah, I threw away my television!” he laughs. “It helps me stay focused and do the things I want to do.”

What does he do at Lightweight? “Our business is split into two parts – the industry business and the sporting goods side. I’m responsible for sporting goods and also part of the management board.” With time ticking on and Christoph due at the show soon, I pedal on and ask him about the ART wheel. Is it a continuation, an evolution? “It’s still very much a Lightweight product – rim-to-rim tech and a monocoque design,” he explains. “It’s the same method of construction that our founder, Heinz Obermayer, created in his garage all those years ago, but it’s a logical progression.” How so? “If you look at the market, rim widths are getting wider and wider, which leads to more applications. When we started, our products were designed for 23mm tires, which, of course, was the standard on the road for a long time. Nowadays, we have numerous applications, from time trial to triathlon, the widening of the road standard, and gravel.”

CHRISTOPH SAWITZKI

Christoph explains that Lightweight’s legacy rim design was always based on a V-shape, which limited the brand’s ability to manufacture wider rims. “With the Meilenstein ART, we use a very special technique to bind the spokes to the rim, which affords us the freedom to make different shapes, from narrow and flat rims to very wide ones.” It sounds like the ART technology could easily flow through to all existing Lightweight models and new ones, too. “Exactly,” nods Christoph. “That’s the plan. Pfadfinder ART, Fenweg ART etc.”

Was there a danger of losing some of the Lightweight magic with such a consequential design change? “We would see it as an improvement,” he counters. “On a descent in windy conditions, the older design could give rise to a sense of nervousness. The new profile design is far more stable. The stiffness is equal to, or even higher than, the prior versions. We also improved the wheel’s aerodynamic performance, which we tested in the tunnel at 45 km/h. We have well-proven systems and a lot of data, so we can be sure of our metrics.”

Given that a Lightweight wheel is the sum total of 20 different production steps and up to 12 specialists, I ask Christoph if producing the Meilenstein ART wheel is similarly involved. “The production is totally different,” he says. “We are using new machines, so we have to educate our people on the new design. It’s very ambitious.” Still, Christoph admits that the challenge facing Lightweight is to progress the ART concept to other wheel models. “The rider wants the freedom to choose between different products. You can’t build a brand on one wheel alone. In that sense, the Meilenstein ART is really the start. The next model will be a gravel wheel, and then we will see!”

Interestingly, for a rider who grew up in the Ullrich era, what excites Christoph the most is the new generation of cyclists, fresh eyes who know only the current epoch. A new wave that knows a wide tire as normal and sees road, gravel and as interchangeable things that give rise to new and ever-changing cultures, tribes and trends. Until that is, the rebirth of pure road and strict delimiters between disciplines. If history and human behavior are anything to go by, we might yet see 23 again. “They inform themselves with a mobile phone – maybe even a chatbot – not a catalog,” says Christoph, of the new consumer. “The challenge for us, and perhaps many brands, is to maintain our existing community and also engage the younger, more lifestyle-oriented consumer. To them, Jan Ullrich doesn’t exist, and that’s normal and healthy. Everything changes.”

On the challenge of moving forward, Christoph provides a recent example that aptly illustrates the bridge, from past to future, that all brands have to cross. “On every wheel up to now, we have included a hub cover. It did nothing but look pretty. And add weight!” he laughs. “So on the new wheel, we removed it. But when our existing customers noticed its omission, many were up in arms. ‘You can’t do that!’ they said. ‘We loved it!’ But for the new wheel, we communicated that it offered no aerodynamic advantage, and actually cost some weight. It was not needed. That sort of push and pull is quite representative of the journey we are on.”

How many years has the new ART tech been in development? Christoph takes a well-earned sip of tea and thinks for a moment. “Well, we had three to four engineers working full-time on this for an equal number of years. Quite a bit of time, I would say.” That time and care is a window into the Lightweight process. “It’s a pretty sharp product, right?” he says. By which I gather he means an example of extreme performance. “Like all Lightweight wheels, the ART Meilenstein is designed at the limit. We’re highly product-focused, and I know most people say that these days. But we really do invest in development. Even so, the market is getting closer and closer. So now, more than ever, we can say that our focus on the highest-quality materials, innovation, and the benefits of making in Germany at our own factory, with people who have been with us for decades and bring a level of experience and knowledge you cannot replicate, matters. Ultimately, we believe in the power of making the best possible product.”

As we rise to leave and walk to the Rouleur show to snap a couple of shots of Christoph and an ART wheel, he tells us a story that reaffirms the reputation of a Lightweight wheel for longevity. “Every so often, we get wheels in for servicing that our founder, Hans Obermayer, built back in the day. And they often have a secret to reveal,” he says, with a twinkle in his eye. “When he had completed each wheel, Hans would put a small handwritten note inside the hub, with the serial number and his signature.” A message in a bottle? “In a way, yes!” laughs Christoph. “That’s sustainability!”

Lightweight wheels are not inexpensive. so it’s gratifying to hear his Hans story. But I’d like to go deeper, so I take the natural segue and ask Christoph about Lightweight’s customer care. “We don’t have a ticket system, no auto replies. A customer can call us or write to us – we don’t force them to go through their dealer, although of course, we do need some documentation. We’re direct, quick to assist and always repair or make things right. That’s what it means to ride a Lightweight wheel.”

The show is starting to fill up, so Adam and I say our goodbyes, with a generous invitation to visit the Lightweight factory in hand (watch this space), and leave Christoph to his day.

As for us, before we see the rest of the show, Adam reaches for his phone and searches for a new coffee shop he’s keen to try. It is a research trip, after all.

FEATURED

Lightweight Meilenstein ART represents a revolution in carbon bike wheel tech. Materially advanced, light, naturally and reassuringly strong, the ART represents the pinnacle of bicycle wheel engineering.